By Richard Parmee, creator and CEO of X-ray examination innovation expert Sapphire Assessment Systems

Assessment of food and drinks to guarantee they are without foreign bodies is a regular function of factory assembly line. However the most recent X-ray examination innovation can do a lot more than discover a piece of metal or glass in a box of chicken nuggets.

Has an item got the right quantity of filling, for instance- and is it uniformly dispersed within the item? Exist any missing out on or harmed products in a multipack? Exists a small speck of sauce caught in the seal of an all set meal- allowing oxygen to ruin the food?

A brand-new generation of examination innovation is using unique real-time insights into all elements of foodstuff- without interfering with conventional factory treatments and high-speed assembly line.

When X-ray examination initially appeared in the mid-1980s, its main function was to change the metal detectors that factories were utilizing to discover roaming pieces of metal in foodstuff. The efficiency of the metal detectors was impacted by a range of aspects such as temperature level changes, metalized product packaging- and even the fat in cheese or meat.

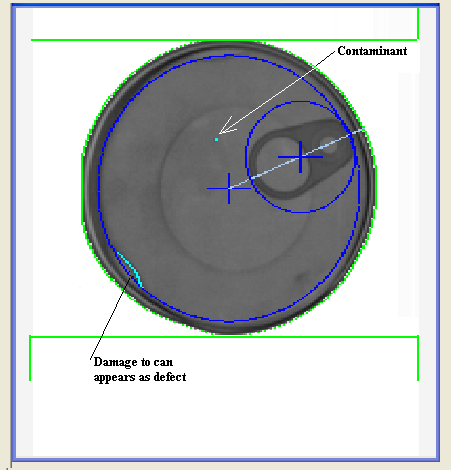

Along with getting rid of these efficiency constraints, X-ray innovation was discovered to be efficient in spotting extra foreign bodies, consisting of glass, bone, ceramics, stone, and particular kinds of plastic. It might even discover such thick pollutants within a container of the very same product- metal in metal, for instance, or glass in glass- as the software application had the ability to factor out the existence of product of consistent density.

Additional advancements in image processing software application now imply X-ray examination systems can consistently mask out functions that would otherwise be viewed as an impurity. The pull tab of a metal can, for instance, might trigger an incorrect turn down as it differs the consistent density of the primary body of the can. However comprehensive info about the geometry of the can suggests the pull tab can be instantly situated and specified as a location of lower level of sensitivity- providing a trusted ways of examination.

The most recent image processing software application can likewise handle the variations in density and shape of glass containers. Glass containers, for instance, can have ridges and bulges, they can be tapered, and the base can typically be thicker. This all needs much higher tolerance from X-ray examination innovation.

Accurate and repeatable measurements of the mass of product within a specific area of an item is another helpful function of X-ray examination. The innovation not just checks the weight of a whole item, it can separately weigh a series of products within the item. So, in a pack consisting of 6 apple pies, the one pie with less filling than the others will be determined and turned down- even if the staying 5 pies have a little excessive filling.

Molded chocolate bars with ingrained wafers can likewise gain from this element of the innovation. If the wafer is missing out on, the molds get filled with chocolate, which is more costly for the producer- costing more than $700,000 each year for a normal assembly line producing in between 4,000 and 8,000 bars per minute.

The very same method can likewise be utilized to inspect that each donut has the right quantity of jelly in it- or that a box of chocolates has the best chocolates in the right positions. It can even inspect that your ready-to-cook meal has all the components you require, or that your sushi lunch is not missing its chopsticks.

Seal examination is another element of food processing taking advantage of the most recent generation of X-ray examination innovation. When the protective gas mix has actually decreased the quantity of oxygen inside the food product packaging, an excellent seal is vital to assist the contents remain fresh for as long as possible. If a salad leaf gets captured up in the seal and is left protruding of a packaged pasta salad, for instance, it will breach the airtight seal and allow oxygen- which will make the item ruin faster and cause waste and client problems. With the most recent X-ray innovation, 2 images are produced from a single detector- one enhanced for the item and one for the seal location. It suggests even the smallest speck of sauce caught in the seal of an all set meal can be discovered.

With the food processing market forecasted to go beyond $4 trillion by 2024, the most recent generation of X-ray examination innovation is playing an essential function- offering a brand-new vision for the future of the market.

Richard Parmee is creator and CEO of X-ray examination innovation expert Sapphire Assessment Systems. Along with developing bespoke services, Richard and his group supply a large range of basic X-ray examination systems to cater for numerous various items in the food, pharmaceutical and cosmetics markets.

Richard Parmee is creator and CEO of X-ray examination innovation expert Sapphire Assessment Systems. Along with developing bespoke services, Richard and his group supply a large range of basic X-ray examination systems to cater for numerous various items in the food, pharmaceutical and cosmetics markets.